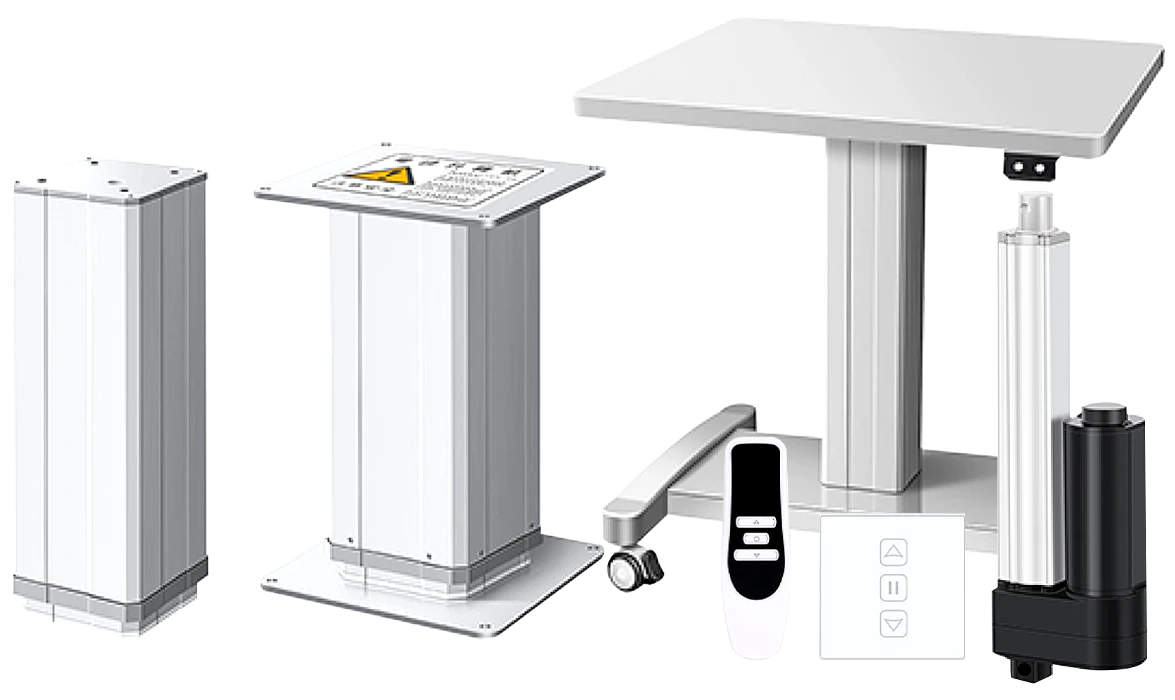

A clean, corrosion-resistant appearance, precise control of raising and lowering, and quiet operation are the stringent requirements placed on actuators in medical environments. Our actuators perfectly meet these requirements, providing excellent service for patients and medical staff.