Technology & Innovation

Hoodland transforms bold ideas into reliable linear motion solutions. From ultra-quiet designs to high IP-rated protection, our technology is engineered for the future of automation, healthcare, and smart living.

- Home

- Technology & Innovation

Technology is more than what’s on paper. It’s built to solve your challenges. Here’s how our core advantages bring real value to you.

Our Core Technologies: Built to Solve Your Toughest Challenges

Instead of listing specs, we focus on how each capability solves the common headaches you face in your projects

Quiet Motion: The End of Unwanted Noise

We've optimized our gears and materials to keep noise below 50 dB—quieter than most offices.

Your Benefit

An end to noise complaints from end-users.

A clear quiet advantage in markets like medical equipment and smart homes.

In-House Controllers: For Truly Simple Customization

The in-house developed IPCE, IPC2, and IPC3 series controllers give us the flexibility to quickly and precisely adjust the control logic and features to your exact needs.

Your Benefit

Significantly shorter project development cycles.

Perfect integration without design compromises.

Extended Lifespan: Reduce Downtime, Save Money

No one likes dealing with products that fail too soon. With a reliable lifespan of over 30,000 cycles , our actuators boast more than twice the durability of industry standards.

Your Benefit

Significantly reduce equipment downtime.

Long-term, reduce maintenance and replacement costs by at least 40%.

High IP Protection: Built for Tough Conditions

From IP54 to IP66, the actuators are built to withstand dust, water, and harsh environments—including explosion-proof options for high-risk industries.

Your Benefit

Equipment operates safely and reliably in harsh environments.

Specialized options for high-risk industries like new energy.

Our Commitments to Your Business

Meet the hearts of innovation: the R&D team.

The team includes mechanical engineers from top universities and senior experts with over 15 years of industry experience. They combine mechanical engineering, electronics, and material science to create smarter, safer, and more efficient motion systems.

The team includes mechanical engineers from top universities and senior experts with over 15 years of industry experience. They combine mechanical engineering, electronics, and material science to create smarter, safer, and more efficient motion systems.

Explore the professional equipment: Each design passes through a rigorous cycle of simulation, prototyping, and field testing before mass production.

Simulation-Driven Design: Get It Right and Faster

We run CAD/CAE simulations before build a single sample. The goal is simple - spotting design flaws early to save you costly reworks and delays.

Rapid Prototyping: Your Ideas in 3 Days

Time is money, especially in the development phase. With the in-house CNC machines, we can turn your design into a working sample in as little as 3 days. This gives you a critical head start on the competition.

Rigorous Testing: Quality You Can Stand Behind

Every product goes through a series of rigorous environmental, endurance, and electrical safety tests. This is to ensure the actuators will deliver consistent, reliable performance in your specific application.

Want to learn more about our production and quality management processes?

Innovation Applied Where It Matters Most

Our solutions are already creating measurable impact in:

Industrial Automation

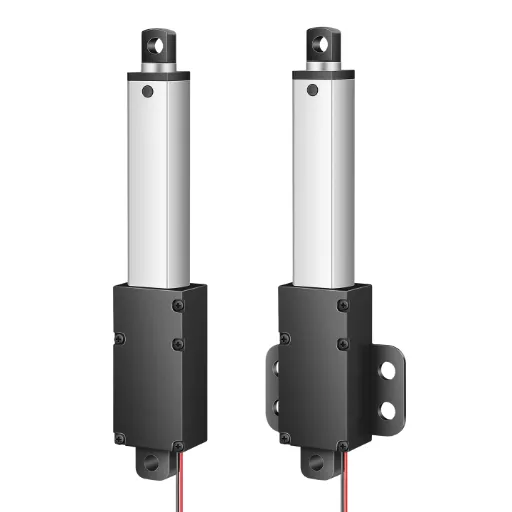

Linear Actuators

A client in the industrial manufacturing sector needed a new lifting platform for their assembly line. The challenge was finding a system that could handle very heavy loads without failing or becoming unstable, which was a major safety and productivity issue for them.

We designed a custom lifting solution with high-capacity linear actuators. Our system featured reinforced internal components and a precisely calibrated control unit to ensure the platform lifted even the heaviest loads smoothly and without any wobble.

The solution delivered immediate value. The new platform significantly improved safety on the assembly line and eliminated a key production bottleneck. This allowed the client to boost their overall production output and reliability.

Medical Equipment

Linear Actuators

A medical device company needed a new actuator for their exam chair, but they had a serious problem: all the standard actuators were too loud and didn't move smoothly. This wasn't just a technical issue, it was affecting patient comfort.

We collaborated with their team to develop a custom, ultra-quiet actuator system. We got the noise level down below 50 dB and added a specialized controller for perfectly smooth motion.

In the end, our solution helped them create an exam chair that's both quiet and reliable. It improved patient experience and made the product a leader in its market.

Smart Living Spaces

Electric Lifting Column

A smart home brand came to us with a challenge: they needed a new lifting column to be clean and clutter-free, with all the power and control cables hidden. It was a tough request, as no one was offering this kind of deep integration.

We got to work with their design team. We customized the top and bottom panels of the column and built the power controller, sockets, and cable management system directly inside.

How about the result? Our client launched a cutting-edge product where form and function were perfectly balanced. The hidden cables made a huge difference, and the product became a hotseller for its awesome integrated design.

Food Production

Industrial Electronic Actuators

Challenge:

A large food manufacturer faced a daunting challenge while upgrading their automated packaging line: the standard actuator mounting base was incompatible with the existing equipment frame. A major retrofit would have resulted in significant downtime and significant costs.

Our Solution:

We responded promptly within 12 hours. Our engineers worked closely with the client's team to create a custom actuator mounting base using in-house CNC cutting technology that perfectly matched the existing equipment.

Results and Value:

Ultimately, our client required no equipment modifications, and the actuators were successfully installed within half an hour. This not only saved the client tens of thousands of yuan in retrofit costs but, more importantly, avoided significant production losses from downtime, ensuring a smooth upgrade of the production line.

Chip Production

Electric Linear Actuators

A high-tech company needed an actuator for their chip manufacturing machine. The problem was that the limited space and high temperatures made standard installation and wiring impossible.

We designed a custom rear mounting interface for the actuator and a specialized power cable with multiple splits. To handle the heat, we reinforced the cables with high-temperature fiberglass tubing. This setup solved their routing and heat protection issues completely.

The solution not only kept the cables safe and organized inside the machine but also ensured the actuator worked reliably in that demanding environment. As a result, the client successfully brought their precision equipment to mass production.

Innovation Patents

Our commitment to advancing linear motion technology is an ongoing journey.

12 national patents have been granted for innovative designs and technologies, with 6 more pending. These patents are more than legal documents—they demonstrate ongoing advancement in linear actuators.